Description

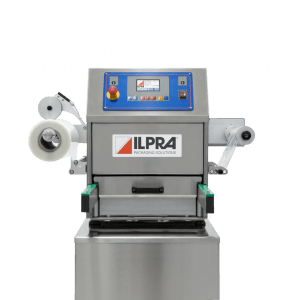

Foodpack Speedy Duo

Speedy Duo is an automatic machine configured with two independent sealing units that can be activated via touchscreen. This mode allows you to eliminate mould changes and gain time for your production . Like the other Ilpra models, the Speedy Duo is highly customisable and can be integrated with other process lines. It was born out of the need to offer an accessible and at the same time ambitious machine for those who require a fast and precise work cycle. The accessible applications are numerous, from simple sealing to vacuum, MAP and various types and classes of packaging skin. The colour touchscreen interface is simple and intuitive, making it easy to use even for inexperienced personnel. In addition, the high degree of customisation of the machine’s components ensures that it can be applied to any type of product to be packaged. Built in stainless steel and complying with IP 65 protection standards, Speedy is a Tray sealer designed to minimise running costs. Reliability, ease of cleaning and maintenance, easy programming and a wide range of customisation options are just some of its strengths. The Ilpra ProGas technology, which is standard on this model, guarantees a higher production speed and therefore greater productivity.

Main Standard Features

| Double chamber |

| Touch screen |

| Total Accessibility |

| Proportional electronic film unwinder |

| Maximum integrability and customization |

Main Options and Accessories

| Print centring system |

| Thermal transfer printer I-PRINT |

| Automatic dosing systems |

| Cup denester |

| Tray Denester |

| Wheels kit |

| Version Skin – Overskin – Extraskin |

| Loading area extension |

Main technical data

| Machine dimensions (mm) – (N – VG) | 3232 x 1030 x 1580h |

| Machine weight (Kg) | approx. 720 (N) – 800 (VG) |

| Air consumption (bar – lt/cycle) – (N / VG) | 6 – 70 (N) / 6 – 75 (VG) |

| Sealing area (mm) – (N / VG) | 380 x 270 x 135 |

Just contact us to discuss and we will find the optimal solution to suit your requirements.